Nye Semicon News - July 2017

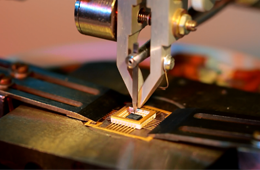

Case Study: Semiconductor Equipment Manufacturer

A company that manufactures semiconductor processing equipment approached Nye about lubricating the rail in a linear guide system. The company wanted to reduce wear in the sliding application. The environmental conditions were high vacuum, and typical operating temperatures ranged between 25°C and 150°C. To prevent contamination and premature failure of the system, the company required a lubricant with low outgassing, excellent friction/wear properties, and low particle generation. Learn how Nye was able to meet all parameters of the customer specification and reduce frictional torque on the sliding surfaces.

A company that manufactures semiconductor processing equipment approached Nye about lubricating the rail in a linear guide system. The company wanted to reduce wear in the sliding application. The environmental conditions were high vacuum, and typical operating temperatures ranged between 25°C and 150°C. To prevent contamination and premature failure of the system, the company required a lubricant with low outgassing, excellent friction/wear properties, and low particle generation. Learn how Nye was able to meet all parameters of the customer specification and reduce frictional torque on the sliding surfaces.

Lubricating Linear Guide Systems

A linear guide system must be able to move side-to-side to perform precise, shifting movements with a smooth, controlled motion. Whether the system is supporting wafer transfer, in-vacuum applications, robotics or manufacturing equipment, such as solar panel, disc drive or flat panel assembly, the entire application must maintain high running accuracy and repeatability. NyeTorr® products have proven success lubricating the guide rails, ball screws, and lead screws in the linear guide systems. These products reduce friction and wear in the guide systems and are recommended for use in vacuum environments as they exhibit excellent vacuum stability, low outgassing, and low particle generation. Download the Linear Guide Application Overview to see which NyeTorr® products are best suited to lubricate the system components.

A linear guide system must be able to move side-to-side to perform precise, shifting movements with a smooth, controlled motion. Whether the system is supporting wafer transfer, in-vacuum applications, robotics or manufacturing equipment, such as solar panel, disc drive or flat panel assembly, the entire application must maintain high running accuracy and repeatability. NyeTorr® products have proven success lubricating the guide rails, ball screws, and lead screws in the linear guide systems. These products reduce friction and wear in the guide systems and are recommended for use in vacuum environments as they exhibit excellent vacuum stability, low outgassing, and low particle generation. Download the Linear Guide Application Overview to see which NyeTorr® products are best suited to lubricate the system components.

Explore our High Vacuum Grease: NyeTorr® 5200

NyeTorr® 5200 was designed to lubricate components within semiconductor manufacturing equipment, such as precision bearings, linear guides, ball screws, and lead screws. This soft, PTFE thickened, medium viscosity, Multiplyalkylated Cyclopentane (MAC) lubricant is ultrafiltered, making it ideal for applications that require very low vapor pressure and particle generation, excellent vacuum stability, and good lubricity film strength. Download the NyeTorr® 5200 Product Overview to learn more about this product.

NyeTorr® 5200 was designed to lubricate components within semiconductor manufacturing equipment, such as precision bearings, linear guides, ball screws, and lead screws. This soft, PTFE thickened, medium viscosity, Multiplyalkylated Cyclopentane (MAC) lubricant is ultrafiltered, making it ideal for applications that require very low vapor pressure and particle generation, excellent vacuum stability, and good lubricity film strength. Download the NyeTorr® 5200 Product Overview to learn more about this product.

![]()