Sulfur and Connector Grease – What You Need to Know

One of the most common questions we get about our connector grease is if it contains sulfur. Engineers are concerned that a grease that contains sulfur, in any form, will interact with terminal metal plating materials, posing a risk to continuity. The short answer is yes, our connector greases contain inactive sulfur. But there is a difference between inactive and active sulfur molecules and how they can affect connector applications.

Inactive sulfur is not harmful to connector applications. But first, let’s explore why sulfur is used in the first place.

Why is Sulfur Used in Grease?

Sulfur is found in many anti-wear, extreme pressure, and antioxidant additives that enable applications to perform under extreme conditions. Sulfur additives have been known to reduce wear on metal surfaces and prevent metal surfaces from welding together.

How Does Sulfur Affect Connectors?

Most connectors are coated with a thin layer of a conductive metal like silver, tin, or copper-tin. These are all reactive metals. Active sulfur, when applied to a connector, reacts with the thin metal coating and creates metal sulfides, or tarnish. When these sulfides build up, they will flake off the surface of the connector and disrupt the surface morphology.

What is the Difference Between In-Active and Active Sulfur?

Not all sulfur is harmful to electric connectors. Active sulfur is harmful to connectors and can result in a loss of continuity, whereas inactive sulfur is not harmful.

Molecules containing active sulfur contain chains of two or more sulfur atoms in length. When sulfur molecules are connected to other sulfur molecules it creates a short chemical chain that can break easily. This break in the chain can result in those molecules interacting with other species. In other words, the chemical structure of active sulfur makes it a reactive material that attacks conductive metal coatings.

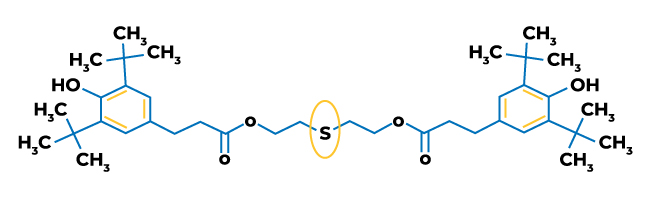

In inactive sulfur compounds, molecules contain fewer than two sulfur atoms in length. In the example shown above, sulfur is connected to carbon or oxygen, which creates a tight chemical structure. Because the structure is so tight, the sulfur molecules do not break off the chain. Thus, they cannot react with the conductive metal coating on the connector surface to create tarnish.

Case Study

Nye chemists ran a series of tests to illustrate the effects of inactive and active sulfur.

Image A shows an untreated silver-plated coupon. The coupon seen in Image B was covered with grease containing inactive sulfur and heated at 100°C for 4 weeks. In this image you can see that the grease protects the coupon surface without creating tarnish.

In Image C, the coupon was coated in a modified grease that does not contain any sulfur and was subjected to the treatment described above. The coupon coated in grease without any sulfur does not tarnish the coupon but is also not protected by the inactive sulfur containing additives which prevent the metal from oxidizing.

Lastly, in Image D a coupon was treated with another modified grease, this time containing active sulfur. The coupon containing active sulfur completely tarnishes the metal surface in just one week and created sulfides that eventually flaked off the metal surface.

These results prove that not only is inactive sulfur safer to use than active sulfur, but inactive sulfur additives improve the overall performance of your connector when compared to a grease without sulfur.

Our Verdict

Not all sulfur is bad for electric connectors! Additives containing inactive sulfur protect components against wear and oxidation without tarnishing conductive metal coatings. To learn more about the benefits of connector grease, click here.

Dr. Amanda Walcott Stubbs – Tribologist

Dr. Amanda Walcott Stubbs – Tribologist

Amanda is the newest addition to Nye’s research and development team. Amanda recently graduated from the Massachusetts Institute of Technology with a PhD in Inorganic Chemistry. At Nye Amanda’s research will dive into how grease affects the metal surface at a chemical level to help us formulate products that meet our customer's needs.

Amanda is the newest addition to Nye’s research and development team. Amanda recently graduated from the Massachusetts Institute of Technology with a PhD in Inorganic Chemistry. At Nye Amanda’s research will dive into how grease affects the metal surface at a chemical level to help us formulate products that meet our customer's needs.