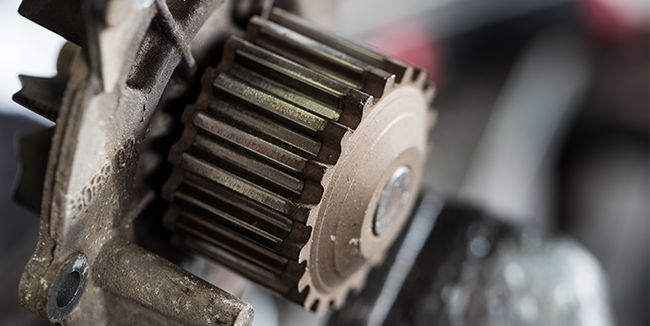

Prevent Wear & Corrosion with Underhood Lubricants

New and emerging environmental regulations require engineers to design internal combustion engines that comply with strict emission standards without sacrificing performance. As a result, OEM’s require engine controls to ensure that both emission and performance requirements are met.

When carefully selected, lubricants for actuators, pumps, and valves can:

- Prevent Corrosion

- Protect Against Wear

- Prevent Fretting

- Enhance Performance

- Improve Reliability

- Extend Component Life

How Do Lubricants Prevent Corrosion?

The automotive underhood environment is the perfect breeding ground for corrosion. Moisture, debris, fuel and exhaust, and fretting can all corrode underhood components. A layer of lubricant seals the component surface to protect the component against oxidation. Lubricants also act as an environmental barrier that keeps dirt, debris, and moisture from reaching the metal surface and accelerating corrosion. To prevent chemical corrosion, a grease with an inert chemistry will remain stable in the presence of fuels and exhaust is required to adequately protect components.

Anti-Corrosion Lubricants from Nye

Nye’s Uniflor™ product line consists of the most advanced Perfluoropolyether (PFPEs) lubricants on the market. These lubricants are chemically inert, water resistant, and stable at extremely high and low temperatures, making them well suited for the harsh underhood environment.

Uniflor™ 8922EL

Uniflor™ 8922EL contains a high-performance additive package for enhanced wear and corrosion protection, providing greater protection and longer life than the legacy PFPE-based bearing greases.

Learn more about Uniflor™ 8922EL